-

1 Weighing

[ The process of weighing raw materials ]Weigh the raw materials (powder / liquid)

Electronic balances and weighing instruments of various sizes are used according to the raw materials.

Raw materials (such as petrolatum) are weighed with drums.

Transfer the raw materials (such as petrolatum) to a melting tank and heating to melt.

The raw materials are aseptically filtered by sterilizing filter.

-

2 Preparation

[ Process of making ointment ]Filtered aseptic raw materials (such as petrolatum) and aseptic raw materials (powder / liquid)are put into the tank and stirred with the paddle mixer in the tank. Raw materials are handled aseptically, so operaters are working in aseptic area.

Transfer the chemical to the transfer tank.

Then transfer the tank from the preparation room to the filling room.

-

3 Filling

[ Process of filling ointment into aluminum tube ]Fill the ointment from the bottom of a sterilized aluminum tube.

After filling, fold the bottom of the aluminum tube with a folding machine to seal.

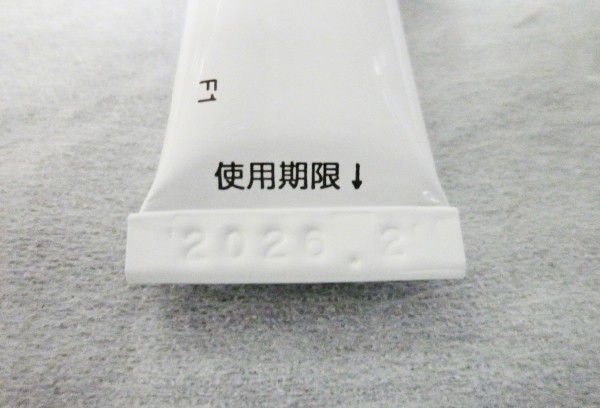

The expiration date and serial number are stamped on the folded part.

Inspection operators inspect the appearance of crushed, scratch, and quality of stamping to aluminum tubes.

-

4 Packing

The product is fitted in a corrugated cushioning material called Rondolation and packed in a box with the package insert.

The box is stamped with a serial number, expiration date, and an identification code called the GS1 code.

Packaging the products into a cardboard box. Products loaded on pallets are stored in an automated warehouse.

-

5 Shipment

Products assured proper quality are shipped to the market.