Guaranteeing Consistent Quality and Reliability.

An Examination System to Prevent Mistakes from Getting Through

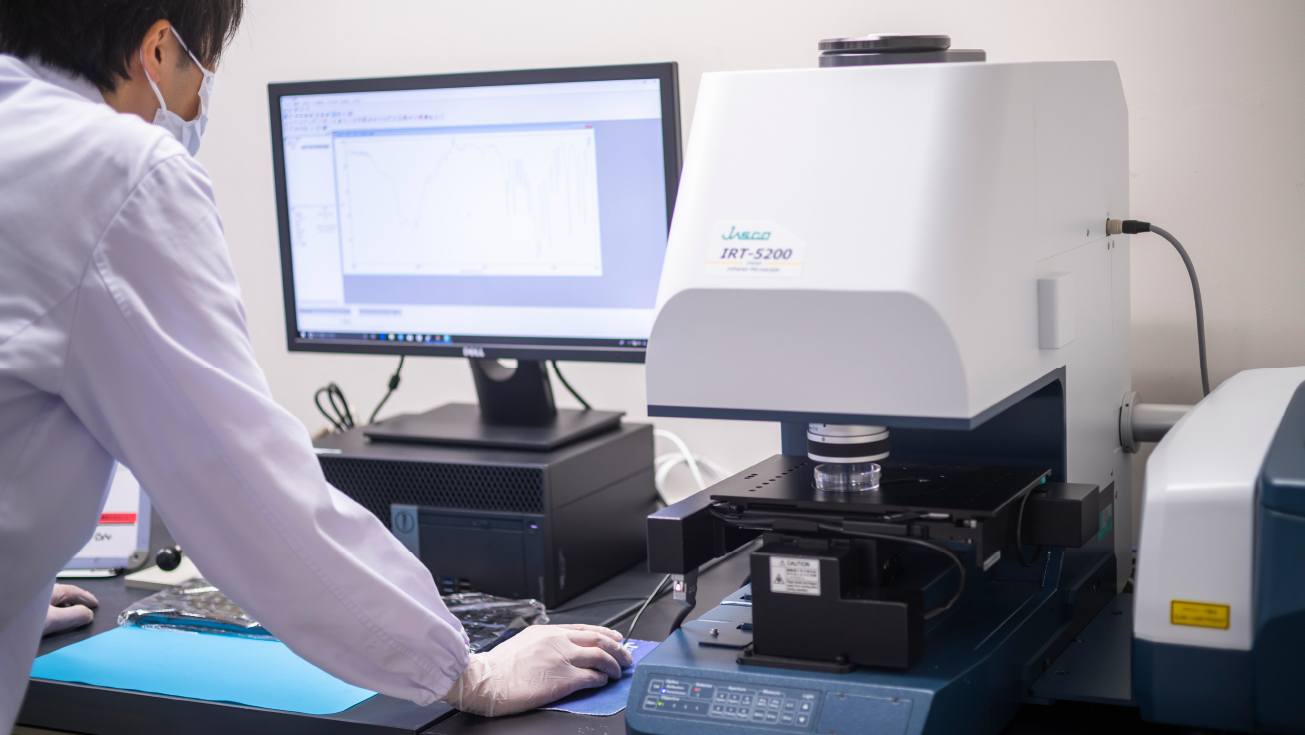

We use an HPLC (high-performance liquid chromatograph), a gas chromatograph, a spectrum photometer system, and more for our inspections, operated by specialized staff for precise, rapid examinations. Our Testing Laboratory, where we carry out sterility testing, features a sterile environment of the highest level, and this environment makes it possible to truly ascertain whether a product is sterile. In addition, we also perform tests on products even after they ship, in order to guarantee their quality through their use-by dates.

Precise Records and the Decision to Ship Products

Based on GMP (Good Manufacturing Practice, standards for manufacturing control and quality control), the staff members involved in manufacturing and testing pharmaceutical products undergo systematic education and training in order to acquire advanced skills. We also keep a great deal of records and data from their work processes. After all stages of production, we make the final decision whether or not to ship the products based on the records from the manufacturing department and the quality department.

Ensuring Quality through Communication

In order to meet customers' demands for ever-higher product quality, we use the technical abilities we have developed over the years related to sterile drugs for external use as a base to allow us to offer specialized products that precisely target users' needs. We believe that providing customers with as much information as possible and engaging in deep, involved communication are both indispensable for maintaining and improving quality.