Environment

Waste Reduction Project

Since 2017, we have been working to reduce the waste generated at the Yatsuo Plant.

Initiatives to Address Environmental Issues

- Reduce defective products and waste liquid by improving the manufacturing process

- Reduce waste by having items that used to be disposed of as wasted purchased for a fee as resource waste.

- Reduce waste by replacing disposable items with those that can be used repeatedly

We have achieved a reduction of up to 40% in waste compared to before the initiative.

Introduction of Biomass Plastic Eye Drop Bottles

As part of our efforts to reduce the environmental burden, we are promoting the use of biomass plastic materials for the container or bottles of our eye drop products. Currently, it has been introduced in some products, and we plan to gradually expand it to other products. The biomass plastic certification mark is displayed on the eye drop bottles made of biomass plastic materials.

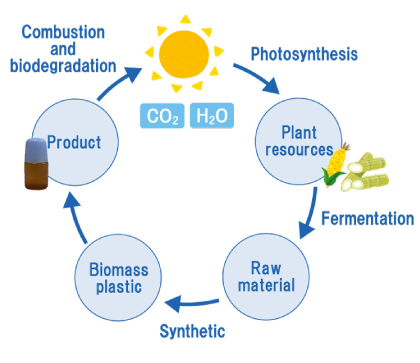

Circulation of biomass plastics

About biomass plastic

Biomass plastics are plastics made from renewable organic resources such as plants. The carbon dioxide emitted from incineration of biomass plastic is carbon dioxide absorbed by the plant as raw material through photosynthesis, and thus does not increase the concentration of carbon dioxide in the atmosphere (carbon neutral). Therefore, it leads to reduction of carbon dioxide emissions and fossil resource consumption, which cause global warming.

About biomass plastic identification display system

The purpose of this system is to enable general consumers to easily identify products made of biomass plastics. It certifies products that meet the specified standards as "biomass plastic" and permits the use of the certification mark.

Efforts to Save Energy

In order to maintain a clean environment, which is essential for the manufacture of pharmaceutical products, we have introduced optimal air conditioning system. For example, the refrigerators and cooling water circulation devices installed in each building were consolidated into one high-efficiency refrigerator, and the steam boilers installed in a distributed manner were integrated into the high-efficiency boiler.

High efficiency boiler

In addition, we are working to save energy by changing equipment and reviewing operation methods.

- Introduction of LED lighting

- Power control by using an inverter

- Replacement with efficient heat source equipment